Your cart is currently empty!

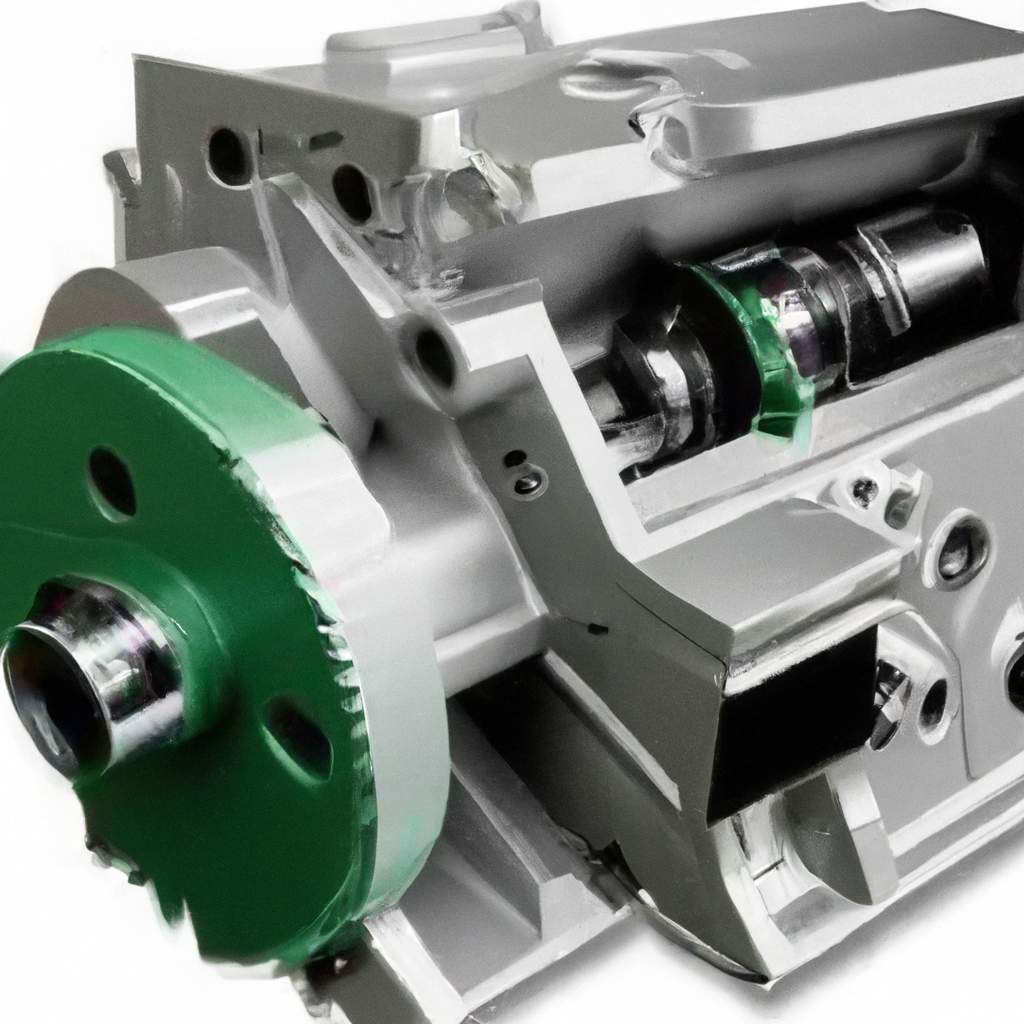

“Maintaining GEHL Engines: Manufacturer’s Guidelines”

GEHL engines are used in a wide range of applications, from agricultural and construction machinery to lawn and garden equipment. As such, it is important to understand how to repair and overhaul these engines in order to ensure they are functioning properly and safely. This article will provide an overview of GEHL engines, identify issues, and provide instructions for repairing and overhauling them, as well as the benefits and potential problems associated with ignoring manufacturer guidelines.

Overview of GEHL Engines

GEHL engines are designed and manufactured by the GEHL Company, which is a global leader in the production of engines for agricultural, construction, and industrial applications. GEHL engines are known for their high performance and reliability, and are used in a variety of applications, from tractors and combines to lawn and garden equipment.

Identifying Issues in GEHL Engines

Before attempting to repair or overhaul a GEHL engine, it is important to identify any potential issues that may be causing it to malfunction. Common issues include worn or damaged parts, fuel or oil leaks, or engine misfires. In order to identify the exact cause of the issue, it is important to consult the manufacturer’s manual or contact a GEHL service center.

Repairing GEHL Engines

Repairing a GEHL engine requires knowledge of the engine’s components and how they interact with each other. It is important to use genuine GEHL parts when repairing the engine, as these are designed specifically for GEHL engines and can help ensure the engine is functioning properly. It is also important to follow the manufacturer’s instructions when repairing the engine, as this can help prevent any further damage or malfunctions.

Overhauling GEHL Engines

The process of overhauling a GEHL engine is similar to that of repairing it, but requires more detailed knowledge of the engine’s components and systems. It is important to follow the manufacturer’s instructions when overhauling the engine, as this can help ensure that all components are correctly installed and functioning properly. Additionally, it is important to use genuine GEHL parts when overhauling the engine, as these are designed specifically for GEHL engines and can help ensure the engine is running at peak performance.

Manufacturer Guidelines for GEHL Engines

In order to ensure that GEHL engines are functioning properly and safely, it is important to follow the manufacturer’s guidelines. These guidelines include instructions for inspecting, maintaining, and repairing the engine, as well as instructions for replacing worn or damaged parts. Additionally, it is important to refer to the manufacturer’s manual when repairing or overhauling the engine, as this can provide detailed information on how to properly diagnose and repair the engine.

Benefits of Following Manufacturer Guidelines

Following the manufacturer’s guidelines when repairing and overhauling GEHL engines can help ensure that the engine is functioning properly and safely. Additionally, following the guidelines can help reduce the risk of further damage or malfunctions, as well as reduce the amount of time and money spent on repairs and maintenance.

Potential Problems When Ignoring Manufacturer Guidelines

Failing to follow the manufacturer’s guidelines when repairing or overhauling a GEHL engine can lead to a variety of problems, including further damage or malfunctions. Additionally, using non-genuine parts can lead to poor performance and reliability, as these parts are not designed specifically for GEHL engines.

In conclusion, repairing and overhauling GEHL engines requires following the manufacturer’s guidelines. Doing so can help ensure that the engine is functioning properly and safely, as well as reduce the risk of further damage or malfunctions. For more information on GEHL engines, please visit https://gehl-manual.com.